Optical Module Knowledge | What are the main causes of optical module failure and protective measures?

The main causes of optical module failure and protective measures

Optical modules must have standardized operation methods in the application, and any irregular action may cause hidden damage or permanent failure.

The main causes of optical module failure

The main causes of optical module failure are deterioration of optical module performance due to ESD damage and optical link failure due to optical port contamination and damage. The main causes of optical port contamination and damage are

The optical port of the optical module is exposed to the environment, and the optical port is contaminated by the entry of dust.

The end face of the fiber optic connector used has been contaminated, and the optical port of the optical module is contaminated twice.

The end face of the optical connector with pigtail is used improperly, such as: end face scratches, etc.

The use of poor quality fiber optic connectors.

How to effectively protect the optical module failure, mainly divided into two kinds of ESD protection and physical protection.

ESD protection

ESD damage is a major problem that causes optical device performance deterioration, and even the loss of device optoelectronic function. In addition, ESD damage to optical devices is not easy to test and screen, if the failure is difficult to quickly locate.

Operating Instructions

Optical modules must be in anti-static packaging during transportation and transfer before use, and must not be removed or placed at will.

Figure 1-4 Module in anti-static packaging box diagram

Figure 1-5 Anti-static marking diagram

Figure 1-6 Schematic diagram of the module in the anti-static bag

Figure 1-6 Schematic diagram of the module in the anti-static bag

Before touching the optical module, you must wear anti-static gloves and anti-static hand ring, and you must also take anti-static measures when installing optical devices (including optical modules).

Figure 1-7 Anti-static gloves diagram

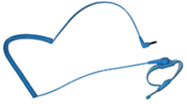

Figure 1-8 Anti-static wristband diagram

Figure 1-8 Anti-static wristband diagram

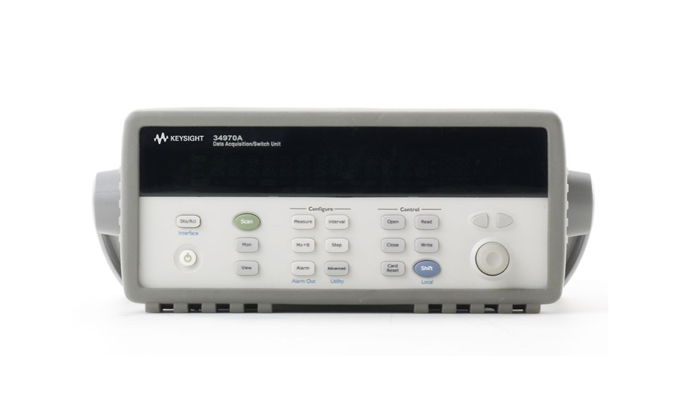

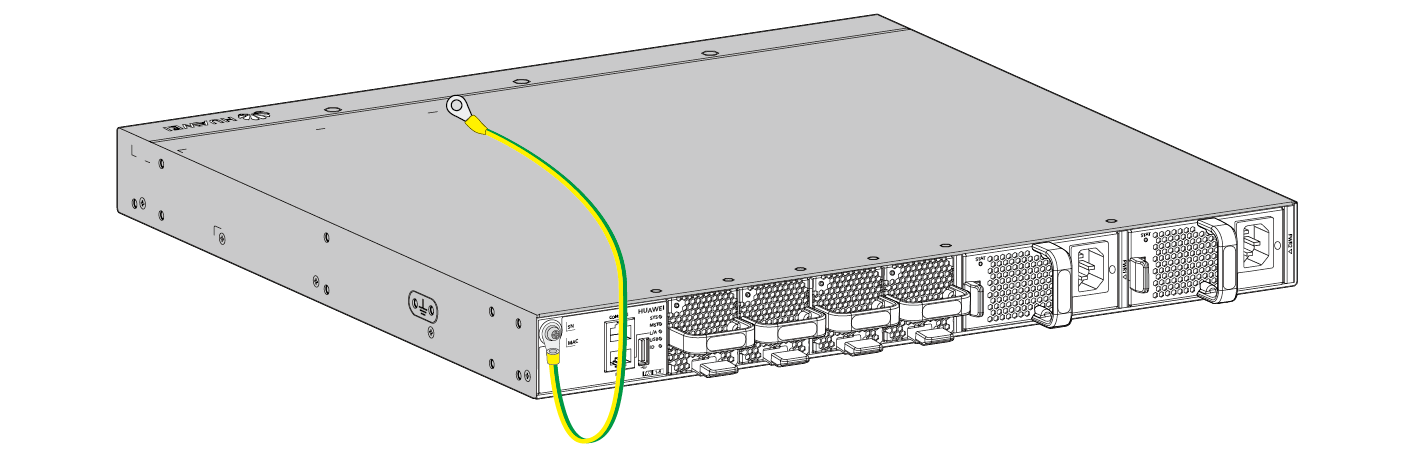

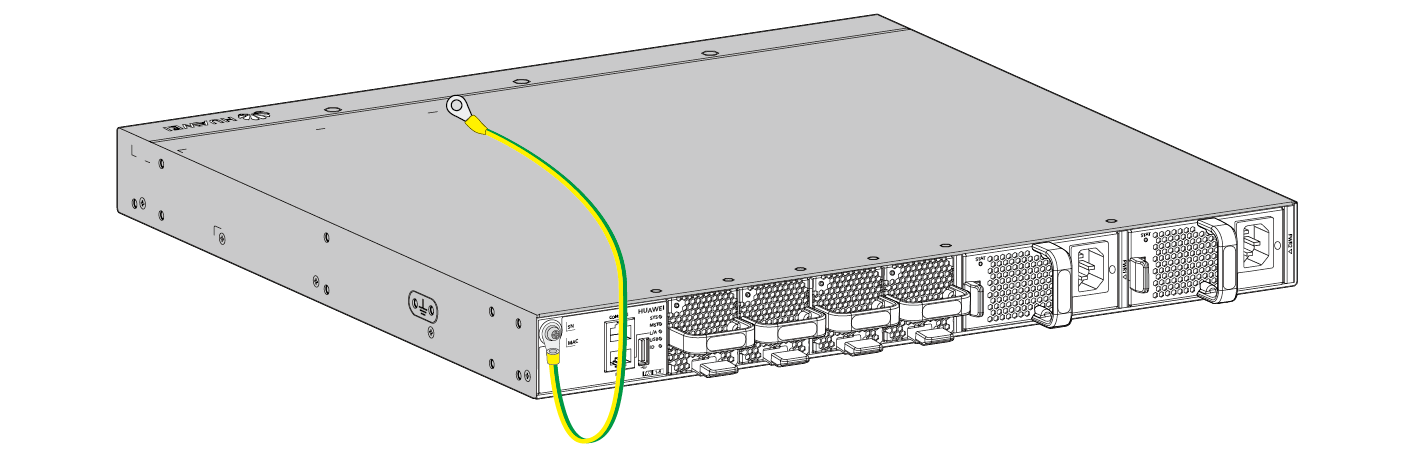

The test equipment or application equipment must have a good grounding wire.

Figure 1-9 Equipment grounding schematic

It is strictly forbidden that for the convenience of installation, the optical modules are taken out from the anti-static packaging and stacked randomly without any protection, just like a scrap recycling bin.

Physical Protection

The laser and temperature control circuit (TEC) inside the optical module are fragile and may break or fall off easily after impact, so physical protection should be paid attention to during transportation and use.

The optical port can be lightly wiped with a cleaning swab, but a non-special cleaning swab may cause damage to the optical port.

The insertion and extraction of optical modules are designed to simulate manual operation, and the design of thrust and tension is also designed to simulate manual operation, and no apparatus should be used for installation and removal.

Operating Instructions

When applying optical modules, pay attention to holding them gently to prevent dropping them.

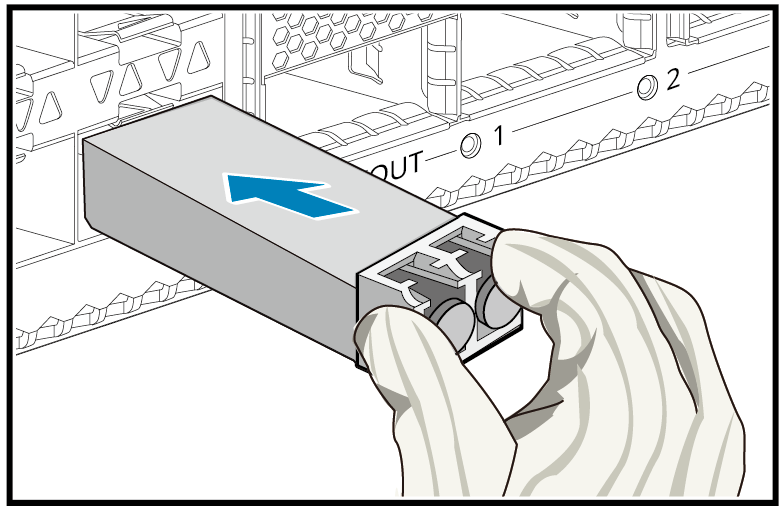

When inserting the optical module, push it in by hand and do not use other metal tools; when pulling it out, open the pull ring to the unlock position first and then pull the ring, and do not use other metal tools.

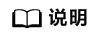

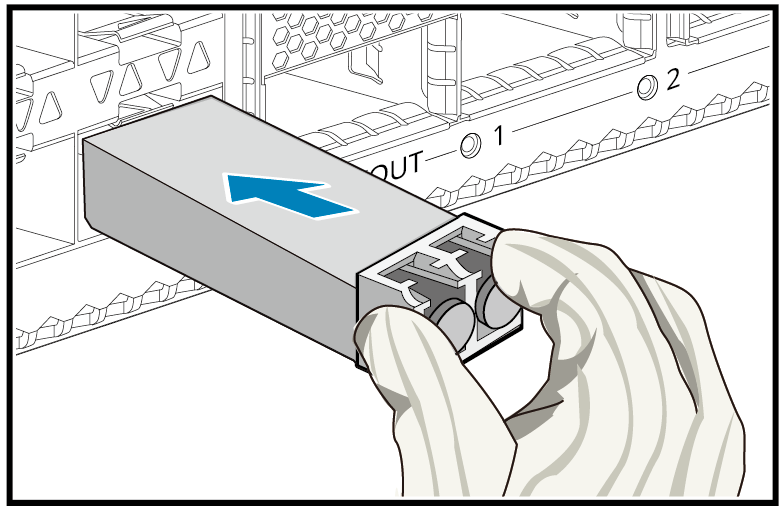

- Figure 1-10 Schematic diagram of optical module installation method

Use special cleaning cotton swabs when cleaning the light port, and do not use other metal substances to insert into the light port.

Figure 1-11 Cleaning optical module optical port with cotton swab

Before touching the optical module, you must wear anti-static gloves and anti-static hand ring, and you must also take anti-static measures when installing optical devices (including optical modules).

Figure 1-7 Anti-static gloves diagramFigure 1-8 Anti-static wristband diagramThe test equipment or application equipment must have a good grounding wire.

Figure 1-9 Equipment grounding schematicIt is strictly forbidden that for the convenience of installation, the optical modules are taken out from the anti-static packaging and stacked randomly without any protection, just like a scrap recycling bin.

Physical Protection

The laser and temperature control circuit (TEC) inside the optical module are fragile and may break or fall off easily after impact, so physical protection should be paid attention to during transportation and use.

The optical port can be lightly wiped with a cleaning swab, but a non-special cleaning swab may cause damage to the optical port.

The insertion and extraction of optical modules are designed to simulate manual operation, and the design of thrust and tension is also designed to simulate manual operation, and no apparatus should be used for installation and removal.

Operating Instructions

When applying optical modules, pay attention to holding them gently to prevent dropping them.

When inserting the optical module, push it in by hand and do not use other metal tools; when pulling it out, open the pull ring to the unlock position first and then pull the ring, and do not use other metal tools.

- Figure 1-10 Schematic diagram of optical module installation method

Use special cleaning cotton swabs when cleaning the light port, and do not use other metal substances to insert into the light port.

Figure 1-11 Cleaning optical module optical port with cotton swab

The main causes of optical module failure and protective measures

Optical modules must have standardized operation methods in the application, and any irregular action may cause hidden damage or permanent failure.

The main causes of optical module failure

The main causes of optical module failure are deterioration of optical module performance due to ESD damage and optical link failure due to optical port contamination and damage. The main causes of optical port contamination and damage are

The optical port of the optical module is exposed to the environment, and the optical port is contaminated by the entry of dust.

The end face of the fiber optic connector used has been contaminated, and the optical port of the optical module is contaminated twice.

The end face of the optical connector with pigtail is used improperly, such as: end face scratches, etc.

The use of poor quality fiber optic connectors.

How to effectively protect the optical module failure, mainly divided into two kinds of ESD protection and physical protection.

ESD protection

ESD damage is a major problem that causes optical device performance deterioration, and even the loss of device optoelectronic function. In addition, ESD damage to optical devices is not easy to test and screen, if the failure is difficult to quickly locate.

Operating Instructions

Optical modules must be in anti-static packaging during transportation and transfer before use, and must not be removed or placed at will.

Figure 1-4 Module in anti-static packaging box diagram

Figure 1-5 Anti-static marking diagram

Figure 1-6 Schematic diagram of the module in the anti-static bag

Figure 1-6 Schematic diagram of the module in the anti-static bag

Before touching the optical module, you must wear anti-static gloves and anti-static hand ring, and you must also take anti-static measures when installing optical devices (including optical modules).

Figure 1-7 Anti-static gloves diagram

Figure 1-8 Anti-static wristband diagram

Figure 1-8 Anti-static wristband diagram

The test equipment or application equipment must have a good grounding wire.

Figure 1-9 Equipment grounding schematic

It is strictly forbidden that for the convenience of installation, the optical modules are taken out from the anti-static packaging and stacked randomly without any protection, just like a scrap recycling bin.

Physical Protection

The laser and temperature control circuit (TEC) inside the optical module are fragile and may break or fall off easily after impact, so physical protection should be paid attention to during transportation and use.

The optical port can be lightly wiped with a cleaning swab, but a non-special cleaning swab may cause damage to the optical port.

The insertion and extraction of optical modules are designed to simulate manual operation, and the design of thrust and tension is also designed to simulate manual operation, and no apparatus should be used for installation and removal.

Operating Instructions

When applying optical modules, pay attention to holding them gently to prevent dropping them.

When inserting the optical module, push it in by hand and do not use other metal tools; when pulling it out, open the pull ring to the unlock position first and then pull the ring, and do not use other metal tools.

- Figure 1-10 Schematic diagram of optical module installation method

Use special cleaning cotton swabs when cleaning the light port, and do not use other metal substances to insert into the light port.

Figure 1-11 Cleaning optical module optical port with cotton swab

Before touching the optical module, you must wear anti-static gloves and anti-static hand ring, and you must also take anti-static measures when installing optical devices (including optical modules).

Figure 1-7 Anti-static gloves diagramFigure 1-8 Anti-static wristband diagramThe test equipment or application equipment must have a good grounding wire.

Figure 1-9 Equipment grounding schematicIt is strictly forbidden that for the convenience of installation, the optical modules are taken out from the anti-static packaging and stacked randomly without any protection, just like a scrap recycling bin.

Physical Protection

The laser and temperature control circuit (TEC) inside the optical module are fragile and may break or fall off easily after impact, so physical protection should be paid attention to during transportation and use.

The optical port can be lightly wiped with a cleaning swab, but a non-special cleaning swab may cause damage to the optical port.

The insertion and extraction of optical modules are designed to simulate manual operation, and the design of thrust and tension is also designed to simulate manual operation, and no apparatus should be used for installation and removal.

Operating Instructions

When applying optical modules, pay attention to holding them gently to prevent dropping them.

When inserting the optical module, push it in by hand and do not use other metal tools; when pulling it out, open the pull ring to the unlock position first and then pull the ring, and do not use other metal tools.

- Figure 1-10 Schematic diagram of optical module installation method

Use special cleaning cotton swabs when cleaning the light port, and do not use other metal substances to insert into the light port.

Figure 1-11 Cleaning optical module optical port with cotton swab